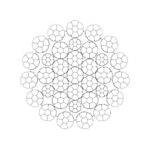

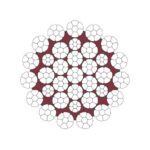

Features of the Steel Wire Rope

Temperature range of use: –40°C to +80°C

Available in ordinary lay and Lang’s lay

Available in right hand and left hand

Available in galvanized and ungalvanized

Available in Plastic Insert and no plastic

High Performance Application

Suitable for multilayer spooling in Lang’s lay

Compacted and Swaged for excellent metal sectional area

Advantage:

1.Non-rotation Rope

2.Recommend hoist in high area.

3.Reduce the wear between wire rope & pulleys.

4.Recommend For single or Multi-layer Coiling

5.Flexible Construction

6.Complete Quality Control system, Make sure the quality is the first aim in production.

7.Galvanized, Bright, Lubricated, Plastic insert, High tensile grade, Coated, Rotation rope, Non-rotation rope and so on.

Application:

Tower Crane(Main Hoist Rope),

Piling Crane(Main Hoist Rope)

Mobile Lattice Boom Crane(Main Hoist Rope),

Quay Crane(Main Hoist Rope),

Offshore Pedestal Crane(Main Hoist Rope),

Overhead Crane(Main Hoist Rope),

Nominal diameter, weight, tensile strength and minimum breaking load define the quality of 34 strand steel wire rope. Following parameters are obtained from sample test and can be used for a reference.

| Construction | Nominal Diameter | Approxi.Weight | Nominal Tensile Strength of rope (MPA) | |||

| D | Unit Weight | 1770 | 1870 | 1960 | 2160 | |

| mm | kg/m | Minimum Breaking Load (KN) | ||||

| 24WxK7 | 8 | 0.32 | 53 | 56 | 59 | 65 |

| 9 | 0.41 | 67 | 71 | 75 | 82 | |

| 10 | 0.5 | 83 | 88 | 92 | 102 | |

| 11 | 0.61 | 101 | 107 | 111 | 123 | |

| 12 | 0.72 | 120 | 127 | 133 | 146 | |

| 35WxK7 or 34xK7 | 13 | 0.85 | 141 | 149 | 156 | 172 |

| 14 | 0.98 | 163 | 172 | 181 | 199 | |

| 15 | 1.13 | 187 | 198 | 207 | 228 | |

| 16 | 1.28 | 213 | 225 | 236 | 260 | |

| 17 | 1.45 | 240 | 254 | 266 | 293 | |

| 18 | 1.62 | 270 | 285 | 298 | 329 | |

| 19 | 1.81 | 300 | 317 | 333 | 366 | |

| 20 | 2 | 333 | 352 | 368 | 406 | |

| 22 | 2.42 | 403 | 426 | 446 | 491 | |

| 24 | 2.88 | 479 | 506 | 531 | 585 | |

| 26 | 3.38 | 562 | 594 | 623 | 686 | |

| 28 | 3.92 | 652 | 689 | 722 | 796 | |

| 30 | 4.5 | 749 | 791 | 829 | 914 | |

| 32 | 5.12 | 852 | 900 | 943 | 1040 | |

| 34 | 5.78 | 962 | 1016 | 1065 | 1174 | |

| 36 | 6.48 | 1078 | 1139 | 1194 | 1316 | |

| 38 | 7.22 | 1201 | 1269 | 1330 | 1466 | |

| 40 | 8 | 1331 | 1406 | 1474 | 1624 | |

| 42 | 8.82 | 1467 | 1550 | 1625 | 1791 | |

| 44 | 9.68 | 1611 | 1702 | 1783 | 1965 | |

| 46 | 10.58 | 1760 | 1859 | 1949 | 2148 | |

| 48 | 11.52 | 1917 | 2025 | 2122 | 2339 | |

| 50 | 12.5 | 2080 | 2198 | 2303 | 2538 | |

| 52 | 13.52 | 2249 | 2376 | 2491 | 2745 | |

| 54 | 14.58 | 2426 | 2563 | 2686 | 2960 | |

| 56 | 15.68 | 2609 | 2756 | 2889 | 3184 | |

| 58 | 16.82 | 2799 | 2957 | 3099 | 3415 | |

| 60 | 18 | 2995 | 3164 | 3316 | 3655 | |

| 62 | 18 | 3198 | 3379 | 3541 | 3902 | |

| 64 | 20.5 | 3407 | 3599 | 3773 | 4158 | |

| 66 | 21.80 | 3624 | 3829 | 4013 | 4422 | |

| 40WxK7 | 68 | 23.10 | 3847 | 4064 | 4260 | 4694 |

| 70 | 24.50 | 4076 | 4306 | 4514 | 4974 | |

| 72 | 25.92 | 4313 | 4557 | 4776 | 5263 | |

| 74 | 27.40 | 4555 | 4812 | 5044 | 5559 | |

| 76 | 28.90 | 4805 | 5076 | 5321 | 5864 | |

Notes:

- Above parameters are used for reference only. Different testing methods and environmental factors such as weather, temperature, humidity, etc. may result in that actual data will be slightly different.

- In addition to industrial standard, GROWORLD can customize steel wire ropes according to your requirements.