The turnbuckle and terminal components are forged from high-quality carbon steel.

The terminal components of the turnbuckle screws have undergone quenching and tempering treatment, and the main body has undergone normalizing heat treatment.

The turnbuckle are hot-dip galvanized.

The breaking force of the turnbuckle is 5 times the working load, and the turnbuckle screw complies with ASME B3026 standard.

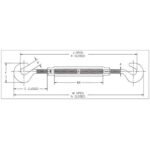

| Code | (in) | (mm) | Working load (T) | Unit weight (Pcs/Kg) | Diemension(mm) | ||||||||

| A | D | E Closed | F | J Open | K Closed | M Open | N Closed | BB | |||||

| GRO01041 | 1/4×4 | 6.35×102 | 0.18 | 0.15 | 6.35 | 11.2 | 42.3 | 32.3 | 249 | 187 | 310 | 208 | 103 |

| GRO05161 | 5/16×4-1/2 | 7.94×114 | 0.32 | 0.24 | 7.94 | 12.7 | 50.7 | 38.1 | 294 | 218 | 358 | 243 | 116 |

| GRO03081 | 3/8×6 | 9.53×152 | 0.45 | 0.38 | 9.53 | 14.2 | 57.8 | 44.7 | 387 | 270 | 453 | 301 | 155 |

| GRO01021 | 1/2×6 | 12.7×152 | 0.68 | 0.85 | 12.7 | 16.5 | 89.7 | 57.9 | 457 | 335 | 527 | 375 | 153 |

| GRO01022 | 1/2×12 | 12.7×305 | 0.68 | 1.26 | 12.7 | 16.5 | 89.2 | 57.9 | 769 | 495 | 839 | 535 | 314 |

| GRO05081 | 5/8×6 | 15.9×152 | 1.02 | 1.46 | 15.9 | 22.9 | 108 | 71.4 | 495 | 368 | 572 | 419 | 153 |

| GRO05082 | 5/8×12 | 15.9×305 | 1.02 | 2.08 | 15.9 | 22.9 | 107 | 71.4 | 809 | 529 | 885 | 580 | 315 |

| GRO03041 | 3/4×6 | 19.1×152 | 1.36 | 1.91 | 19.1 | 24.9 | 129 | 84.6 | 538 | 406 | 620 | 467 | 156 |

| GRO03042 | 3/4×12 | 19.1×305 | 1.36 | 3.14 | 19.1 | 24.9 | 128 | 84.6 | 853 | 568 | 935 | 630 | 320 |

| GRO03043 | 3/4×18 | 18.1×457 | 1.36 | 3.92 | 19.1 | 24.9 | 129 | 84.6 | 1158 | 721 | 1240 | 782 | 471 |

| GRO07081 | 7/8×12 | 22.2×305 | 1.81 | 4.47 | 22.2 | 28.7 | 148 | 96.0 | 886 | 597 | 972 | 667 | 309 |

| GRO10001 | 1×12 | 25.4×305 | 2.27 | 6.70 | 25.4 | 31.8 | 167 | 108 | 929 | 637 | 1019 | 714 | 309 |